| | E-MAIL | |

|

RTP VS TCP PIPES Reinforced Thermoplastic Pipe / Thermoplastic Composite Pipe in the Oil and Gas Industriesorced Applications of RTP/TCP pipes of product in the transport of oilfield fluids, in gas transmission and in subsea flowlines |

NOT ALL PIPES ARE THE SAME

The choice of materials for use in oil and gas pipelines and hydrocarbon transportation can affect operating costs, lead times, regulatory compliance, ease of installation, maintenance costs, total cost of ownership and more.

While fiberglass pipes are used to transport petroleum products and natural gas, existing dry fiberglass and thermoset resin products may no longer be the best option for various reasons.

More advanced products are available such as Reinforced Thermoplastic Pipes (RTP) and Thermoplastic composite pipes (TCP) based on glass fibre, carbon fibre, basalt or aramid fibers in a thermoplastic matrix. They are gaining popularity among operators and engineers in the oil and gas industry because this type of pipe can withstand extreme conditions and is not subject to common problems that other fiberglass products are subject to.

Pipe strength is reinforcement

RTP/TCP pipes are an alternative to traditional piping materials. These are coiled flexible tubes that provide high pressure, corrosion resistance, reliability, strength and proven plant efficiency.

Major applications include oil and gas gathering and water pumping.

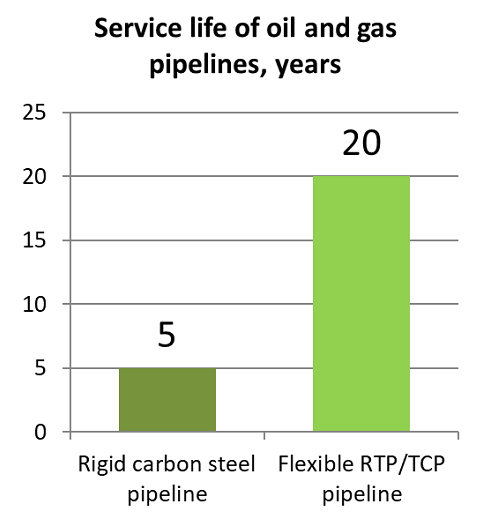

Extended service life of oil and gas pipelines

Polymer-reinforced RTP/TCP thermoplastic pipes are as corrosion resistant as GRP pipes and more durable than steel pipes.

They can resist salt corrosion as well as H2S/CO2 corrosion. This contributes to a longer service life of the entire system at no additional cost.

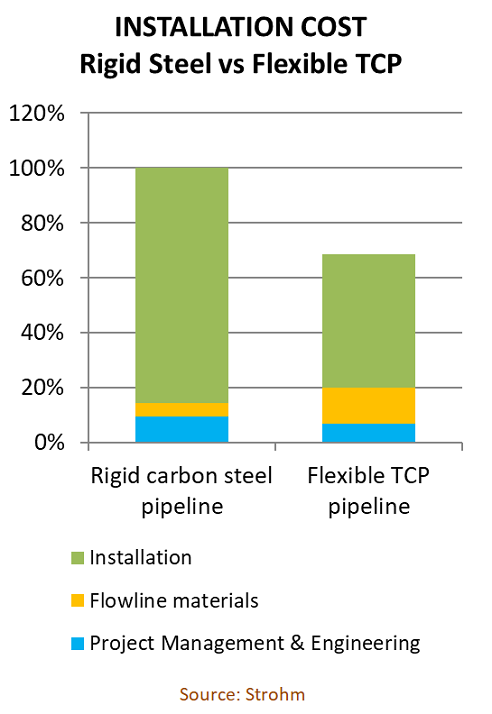

Ease of installation and lower cost of ownership

The installation process of RTP/TCP is less labor intensive and takes less time than other options as they optimize operations while minimizing security concerns. RTP/TCP reeling capability reduces setup and downtime, while flexibility allows RTP/TCP to be used in challenging environments.

Ease of maintenance and total cost of ownership

Corrosion-resistant RTP/TCP materials reduce piping failures, and their flexibility requires fewer connections and ensures system tightness.

Liner options allow customization to suit specific applications, allowing the properties of selected materials to suit a variety of operating conditions, minimizing maintenance and total cost of ownership.

The growing adoption of TCP is due to its many savings advantages over conventional pipes. For example, despite the higher cost of materials, Strohm's highest performance carbon fiber/PVDF in flowlines results in a 30 percent savings in installation cost compared to metal flowlines.

WHAT IS RTP AND TCP PIPES?

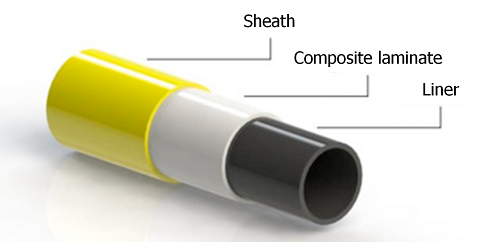

Reinforced thermoplastic pipe (RTP), also known as flexible thermoplastic composite pipe (TCP), is a general term. This is an alternative to traditional pipes. They consist of three main layers: a thermoplastic liner, a helically wound continuous reinforcement system of high strength fiber or UD tapes, and an outer thermoplastic sheath.

Typically, the construction uses Polyethylene (HDPE), Polyamide (PA12), Polyethylene of Raised Temperature resistance (PE-RT), Polyvinylidene fluoride (PVDF), or Polyetheretherketone (PEEK) and reinforcement with glass fiber, aramid or polyester fiber, carbon fiber or high-strength steel wire or tape, unidirectional fiber reinforced thermoplastic tape (UD tape), although other combinations are used.

Recent innovations include RTP/TCP for high operating temperatures and gas-tight, including for hydrogen - TCP-DGB.

Some generalization of RTP/TCP terms creates some confusion. Often even equipment manufacturers do not pay attention to the subtleties of terminology and Thermoplastic composite pipes are called Reinforced Thermoplastic Pipes, and vice versa.

But RTP and TCP pipelines have fundamental differences

Both RTP pipe and TCP pipe consist of three main layers: a thermoplastic liner, a fiber reinforcement system, and an outer thermoplastic layer.

RTP. Reinforced Thermoplastic Pipes

The reinforcement layer of RTP pipes is an unbonded structure that consists of separate, unbonded polymer and metal layers, which allows relative movement between the layers. A reinforcing layer, often consisting of dry fibres, metal wires or tapes, is wound around the liner and protected by an outer sheath.

They are used at lower pressures and less demanding temperatures than fully bonded TCP pipe.

Destruction of RTP reinforced with polymer threads due to excessive hydraulic pressure

TCP. Thermoplastic composite pipes

TCP is a Fully bonded structure in which all three layers are fully bonded (fused) to each other. A reinforcement layer of UD tapes wound around the liner and fused to each other reinforced with unidirectional continuous fibers (eg fiberglass, carbon, aramid fibers) is integrated and fused to the liner and outer sheath.

They are suitable for higher pressures and a wider temperature range for the following reasons.

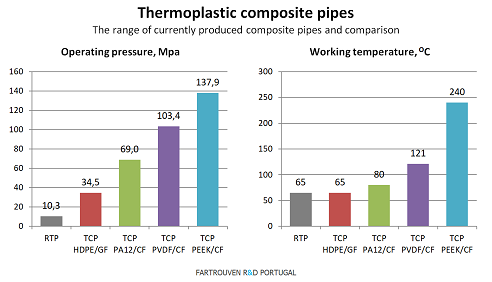

First, some fully bonded TCPs use not only HDPE with fiberglass but also higher performance thermoplastic resins such as PA-12, PVDF, PEEK with carbon fiber.

Secondly, the reinforcement layers of TCP pipes are bonded to each other by melting, resulting in a pipe that is a composite structure, which provides better performance than RTPs made from the same materials.

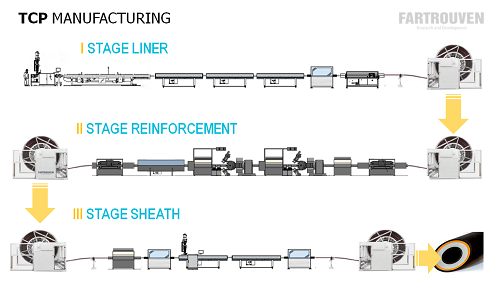

HOW TCP IS MANUFACTURED

TCP is built in three continuous steps.

First, a thermoplastic liner is extruded. The tape is then automatically laid down with wrap-in-place from several to 100 layers of fibre-reinforced thermoplastic tape (UD tape), with each layer fused to the previous layers. Finally, the reinforced liner goes through a third stage where the outer sheath is applied. As Nelson Bernardo (Fartouven R&D) explains, oversheathing is not conventional co-extrusion. “We melt the outer composite layer and pressure coat the composite. The result is a pipe with high shear strength between the coating and the composite layer, allowing our customers to produce TCP anywhere while maintaining a high strength, durable and protective coating.”

TCP ON LAND AND AT SEA

It is important to note that the development of TCP was accompanied by the creation of a formal standard (DNV GL ST-F119) for the design and validation of TCPs in subsea applications. The road to this standard has been painstaking, but the result is a document and guide that gives energy professionals greater confidence in the long-term performance of the product, as well as the expected cost of using it. Such confidence, as one might imagine, is critical in an industry as highly regulated and closely monitored as offshore oil and gas, where pipe failure is simply unacceptable. The DNV GL ST-F119 standard covers the qualification of basic materials as well as the design method and, of course, the production technology.

The separate qualification of all basic materials and only then the design and production of pipes of any size from these quality materials is the guarantee of TCP quality.TCP Can handle the pressure of up to 689 bar/10 000 psi (TCP=10× RTP )

It can be used in 3,000 mwd and has been proven with 2,140 mwd. Does not require additional measures for gas services and can efficiently handle all services which include sweet and sour crude, gas and the whole well stream. Can go up to 7.75 in true bore liner diameter manufactured in a continuous length of at least 3,000 m. Also, the maximum applied length per spool relies on permitted drum size, notwithstanding a standard road conveyed drums can be provided in lengths of at least 600 m.

~65 °C and 5 ksi (34,5 MPa) / Water, methanol, Hydrocarbons, acids

~80 °C and 10 ksi (69,0 MPa) / Hydrocarbons, seawater

~121 °C and 15 ksi (103,4 MPa) / Hydrocarbons

Used onshore and in offshore shallow water of about 30 m. Cannot handle gas service in high pressure (42 bar maximum operating pressure) and requires additional procedures to be carried out e.g. gas venting. Limited true liner bore diameter of 5.6 in inner diameter can be supplied at a length of 300 m per pool

Source: Obinna Okolie, Jim Latto, Nadimul Faisal, Harvey Jamieson, Arindam Mukherji & James Njuguna. Manufacturing Defects in Thermoplastic Composite Pipes and Their Effect on the in-situ Performance of Thermoplastic Composite Pipes in Oil and Gas Applications. Applied Composite Materials volume 30, pages 231–306 (2023)

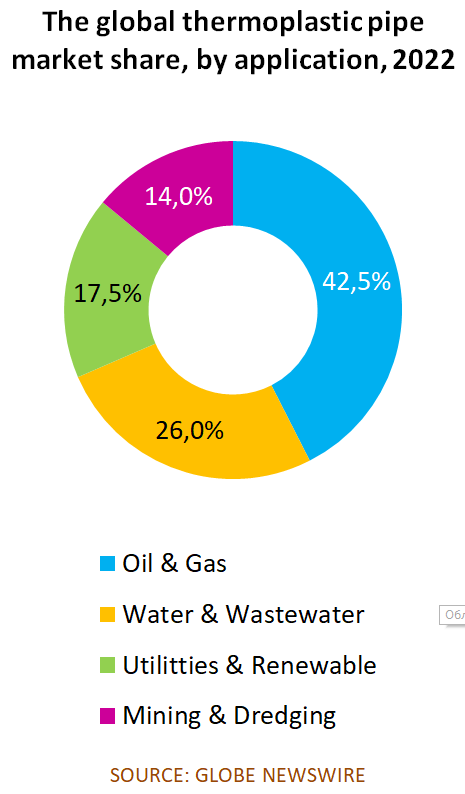

THERMOPLASTIC PIPES MARKET

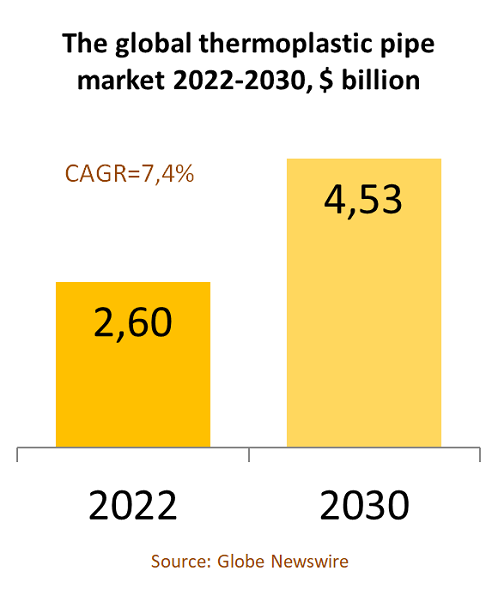

Global Thermoplastic Pipes Market to Reach $4.5 Billion by 2030

In the changed post COVID-19 business landscape, the global market for Thermoplastic Composite Pipes estimated at US$2.6 Billion in the year 2022, is projected to reach a revised size of US$4.5 Billion by 2030, growing at aCAGR of 7.4% over the period 2022-2030.

Reinforced Thermoplastic Pipe, one of the segments analyzed in the report, is projected to record 7.2% CAGR and reach US$2.9 Billion by the end of the analysis period.

Taking into account the ongoing post pandemic recovery, growth in the Thermoplastic Composite Pipe segment is readjusted to a revised 7.8% CAGR for the next 8-year period.

The growing demand from the oil and gas industry for corrosion resistant pipes is expected to drive the growth of the thermoplastic composite pipe market in the future. Pipeline corrosion is the oxidation and electrochemical destruction of the pipe structure.

The use of thermoplastics in the production and transportation of oil and gas is becoming a practical and reliable solution to reduce corrosion. These pipelines are lighter and more resistant to corrosion than metal pipelines, allowing oil and gas corporations to explore and produce in deeper offshore oil fields.

For example, in May 2020, according to Oil Review Middle East, a Middle East oil and gas journal, the annual cost of corrosion for the oil and gas industry worldwide is estimated at more than $60 billion, in the US alone. estimated at about $27 billion.

In terms of refining, the global cost of refinery corrosion is estimated at US$15 billion per year in the region.

Thus, the growing demand from the oil and gas industry for corrosion-resistant pipes is driving the market for thermoplastic pipes.

SPACE ACCELERATION OF TCP PRODUCTION

In preparation to meet growing demand, many companies such as Strohm are executing for the fifth time a three-year program aimed at increasing the company's production capacity in one year.CONSULTATIONS

Consulting on the organization of production of thermoplastic composite pipes TCP

e-mail: plant@fartrouven.pt

PIPE MANUFACTURING EQUIPMENT

PLANT TURNKEY

|

FARTROUVEN R&D

.

Rua Campo de Futebol, 308 Ruivaqueira 2425-480 Souto da Carpalhosa, Portugal

www.fartrouven.pt

Portugal +351 244 130 855

CIS countries +7 985 087 40 86

e-mail: geral@fartrouven.pt

© FARTROUVEN R&D PORTUGAL 2012-2025