| | E-MAIL | |

|

INTERESTING INVENTIONS ARE BORN AT THE INTERFACE BETWEEN DIFFERENT SCIENCES Specialists of various areas of science unite their efforts, and as a result, bright and unusual discoveries appear |

INNOVATIVE DEVELOPMENT

Multilayer composite and hybrid materials are the most dynamically developing segment of science and technology.

In this area, at the junction of various sciences, bright, unusual discoveries, interesting inventions appear.

The experience of creating extrusion equipment and research in the field of plasma formed the basis of new technologies, equipment and a new generation of composite pipes.

By combining composite technologies with high-energy surface modification technologies, we have created:

New technologies for the production of multilayer composite pipes MLSC for the construction industry and housing and communal services;

And new properties for flexible high-pressure thermoplastic composite pipe TCP for the oil and gas industry, and hydrogen energy.

COMPOSITE TECHNOLOGIES

Treatment by ion beams and plasma are modern methods of active action on the surface.

The surface properties can also be modified by thin film deposition.

.

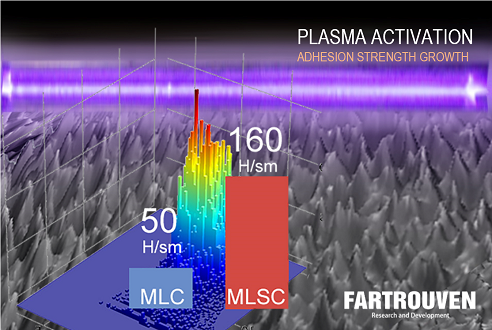

A key element of modern composite technologies is the surface. Its structure, energy and topology determine the properties of the product (corrosion resistance, hardness, chemical activity) or, for example, the quality of the junction, if it is carried out on this surface.

It is for this reason that we pay special attention to the activation and modification of the surface. The ability to manage the properties of surfaces is the key to successfully solving most technological problems.

It is the ability to control the properties of the surfaces of multilayer pipes that allowed us to reach a new technological level.

By modifying the surface of the metal layer in a multilayer pipe, we increased its resistance to delamination, internal pressure, water hammer, extended its service life and made it weldable for inexpensive polymer fittings.

By acting on the surface of aramid fibers (Kevlar, Nomex, Kermel), fiberglass, carbon fiber, fibers from ultra high molecular weight polyethylene (UHMW PE, HM PE), we have obtained a flexible, durable polymer matrix in composite pipes for the oil and gas industry and hydrogen energy.

We develop wide range of technologies for tailoring of surface properties:

- Formation of nano and micro relief in a spark and glow discharge plasma

- Ion implantation and ion-diffusion saturation of the surface with doping elements

- High-performance ion-plasma coating methods

The development of modern technologies is a science-intensive task which requires the efforts and knowledge of highly qualified specialists. We have combined a team of engineers and scientists from various countries to solve these problems, able to offer our customers new technologies, high-tech equipment and new technical solutions.

The Fartrouven R&D team is happy to help you with your industrial projects.

PIPE EQUIPMENT

PLANT TURNKEY

FARTROUVEN R&D

.

Rua Campo de Futebol, 308 Ruivaqueira 2425-480 Souto da Carpalhosa, Portugal

www.fartrouven.pt

Portugal +351 244 130 855

CIS countries +7 985 087 40 86

e-mail: geral@fartrouven.pt

© FARTROUVEN R&D PORTUGAL 2012-2025