| | E-MAIL | |

|

Defect Formation: The Case for Automation In essence, the process of defect-free TCP manufacturing is a multidimensional task that requires precision, control, and adaptability |

Automated Control Systems in the Manufacturing Process of Thermoplastic Composite Pipes

Author: Michael Popov, Nelson Bernardo (Fartrouven R&D)

Abstract

In the production of Thermoplastic Composite Pipes (TCP)—increasingly adopted in the energy industry for their lightweight, corrosion-resistant, and high-performance properties—the assurance of defect-free manufacturing is paramount. This article emphasizes the central role of automated process control systems in achieving consistent quality, minimizing manufacturing defects, and optimizing productivity. Through precise monitoring and real-time adjustment of key parameters—such as temperature, compaction force, layup speed, and material alignment—automated systems offer a transformative solution to the challenges currently limiting the scalability and reliability of TCP manufacturing.

1. Introduction

Thermoplastic Composite Pipes (TCP) are revolutionizing pipeline technology, particularly in the oil and gas sector, by offering a flexible, corrosion-resistant, and spoolable alternative to conventional steel pipelines. However, the benefits of TCP can only be fully realized when the manufacturing process ensures structural integrity and defect-free performance.

Although production equipment exists for both one-stage and two-stage processes, the most robust and stable approach is the three-stage TCP manufacturing process.

Given the complex thermo-mechanical interactions during TCP production, automated process control systems are no longer optional—they are a critical component of modern composite pipe manufacturing lines. These systems form the foundation for process repeatability, defect prevention, and performance assurance.

2. Defect Formation: The Case for Automation

2.1 Common Manufacturing Defects

TCP manufacturing is prone to defects such as:

- Voids and porosity due to air entrapment or insufficient compaction;

- Delamination caused by uneven heating or poor fusion bonding;

- Fibre misalignment resulting from mechanical inconsistencies during layup;

- Thermal degradation due to uncontrolled heating.

These defects often stem from unmonitored variations in process parameters, making real-time detection and correction through automation essential.

2.2 Risks of Manual or Semi-Automated Control

Manual or semi-automated processes lack the consistency and responsiveness required for high-quality TCP production. Delayed responses to parameter deviations increase the risk of cumulative defects, production downtime, and rejected output.

3. The Role of Automated Process Control Systems

3.1 Real-Time Monitoring and Adjustment

Automated systems continuously monitor critical parameters, including:

- Surface temperature at the nip point;

- Roller pressure and compaction force;

- Layup speed and feed tension;

- Tape alignment and bonding quality.

Any deviation from predefined thresholds triggers immediate corrective action, maintaining stability across all production stages.

3.2 Integration with Heating Systems

Thermal consolidation is especially sensitive in TCP production. Automated control systems:

- Adjust laser intensity or infrared radiation based on real-time thermal imaging;

- Prevent overheating or underheating at the fusion interface;

- Synchronize heat application with line speed and material thickness.

By integrating heating control with motion and force feedback systems, automation ensures optimal bonding without degrading the polymer matrix.

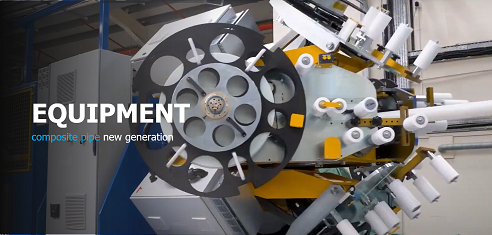

3.3 Automated Tape Laying with a Wrapping Machine

In TCP production, automated tape laying (ATL) is implemented using a wrapping machine, which ensures continuous and uniform winding of pre-impregnated thermoplastic tapes onto an extruded liner.

This system includes:

- Path control systems to maintain ply orientation;

- Vision systems to detect misalignment;

- Synchronization with heating sources (e.g., IR oven) for in-situ consolidation of layers;

- Feedback loops to adjust tension and correct anomalies.

The integration of the wrapping machine with an automated control system enables rapid adjustment of winding speed, clamping force, and temperature parameters—critical for preventing porosity, delamination, and fibre displacement.

4. Benefits of Automation in TCP Production

Limited

High

5. Recommendations for Implementation

To ensure the successful integration of automated control in TCP manufacturing, the following steps are recommended:

5.1 Sensor and Data System Design

- Use infrared cameras, laser profilometers, and force sensors to track key process variables.

- Ensure high data acquisition rates for accurate process control and mapping.

5.2 Closed-Loop Feedback Systems

- Implement PID controllers or machine-learning-based algorithms to adjust heat source power, roller pressure, and line speed in real time.

5.3 Predictive Maintenance

- Integrate automation with diagnostic tools to detect wear in heating elements or mechanical drift in compaction rollers before defects occur.

5.4 Human-Machine Interfaces (HMI)

- Equip operators with intuitive dashboards to visualize performance metrics, alarms, and process trends for proactive decision-making.

6. Conclusion

In essence, the process of defect-free TCP manufacturing is a multidimensional task that requires precision, control, and adaptability.

The path to high-quality, defect-free TCP lies in the full integration of automated process control systems. These systems deliver unmatched accuracy, consistency, and efficiency in managing complex composite manufacturing environments. By transitioning from manual correction to predictive, real-time response, automation enhances product quality, minimizes waste, increases throughput, and strengthens long-term operational reliability.

In today’s market—where performance and safety standards are rising—investment in automation is not merely an upgrade. It is a strategic necessity for any TCP manufacturer aiming for technological leadership and operational excellence.

© Fartrouven R&D 2025

CONSULTATIONS

Consulting on the organization of production of thermoplastic composite pipes TCP

e-mail: plant@fartrouven.pt

PIPE MANUFACTURING EQUIPMENT

PLANT TURNKEY

FARTROUVEN R&D

.

Rua Campo de Futebol, 308 Ruivaqueira 2425-480 Souto da Carpalhosa, Portugal

www.fartrouven.pt

Portugal +351 244 130 855

CIS countries +7 985 087 40 86

e-mail: geral@fartrouven.pt

© FARTROUVEN R&D PORTUGAL 2012-2025